BARREL ZINC NICKEL PLATING

Overview

Zinc-nickel has increasingly become the finish of choice for many industries with high-corrosion and high-performance needs as it can bestow better anti-corrosion protection with a thinner coating than zinc plating alone. It is a rapidly growing segment of the electroplating market driven largely by the needs of the automotive industry, but it is also rapidly gaining a growing appreciation in other industry sectors.

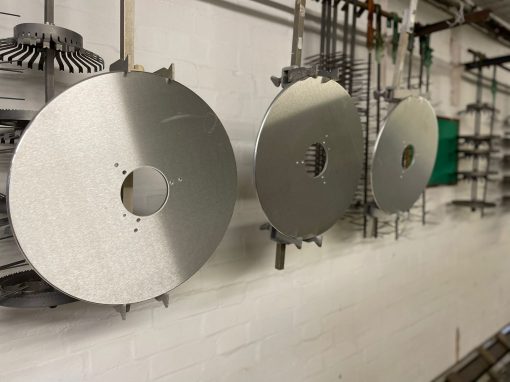

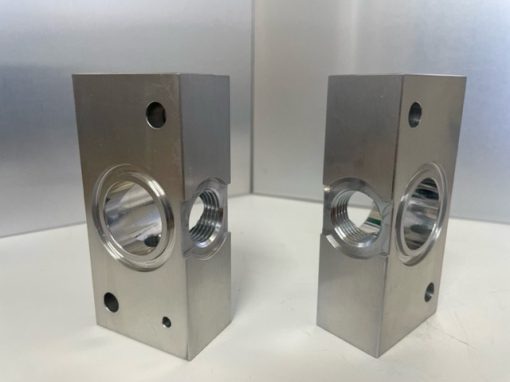

Zinc nickel plating can be achieved via an acid or alkaline plating solution. TWB Finishing are one of the few UK suppliers able to offer Acid Zinc Nickel. The main benefit of Acid Zinc Nickel over Alkaline is the finished appearance. Whereas alkaline Zinc Nickel typically confers a dull matt finish, parts treated with acid Zinc Nickel can be finished to give a mirrored chrome-like appearance.

Work Envelope

Any parts suitable for barrel plating

Suitable Substrate

Steel

Post Treatments

Blue, clear and black passivates available with High end seal

Benefits

- Excellent resistance to corrosion and mechanical wear

- Compact deposit with good thickness uniformity

- Confers high electrical conductivity

- Compatible with a wide range of sealants and passivates that can further increase the resistance to corrosion whilst also giving a uniform-coloured look

- Acid Zinc Nickel offers a superior polished and bright aesthetic than is achievable with traditional Alkaline Zinc Nickel

Uses

Zinc Nickel is used extensively across a range of industries such as automotive, defence, oil & gas, marine and electronics. It is widely used in the automotive industry to provide high corrosion protection to various automotive parts since Zinc-nickel serves as a sacrificial coating and will corrode before the underlying base material.

The electrical transmission industry also makes use of zinc-nickel plating due to its high electrical conductivity in the manufacturing of anchors, coaxial cables and cleat bolts. Whilst the aerospace and defense industries have moved rapidly towards zinc-nickel plating as an eco-friendly replacement for cadmium plating.

For more information about this service or any other please contact us