Overview

Zinc plating provides a high quality, durable finish to steel parts. The zinc coating protects the parts from the effects of wear and tear as well as helping prevent corrosion and abrasion.

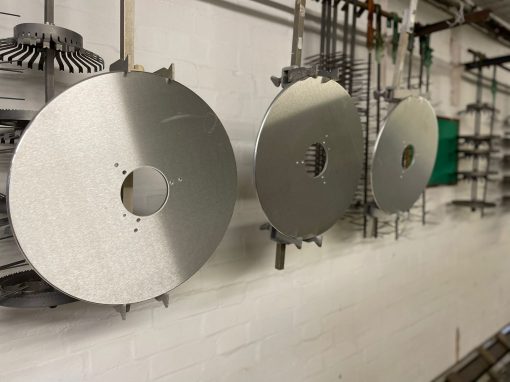

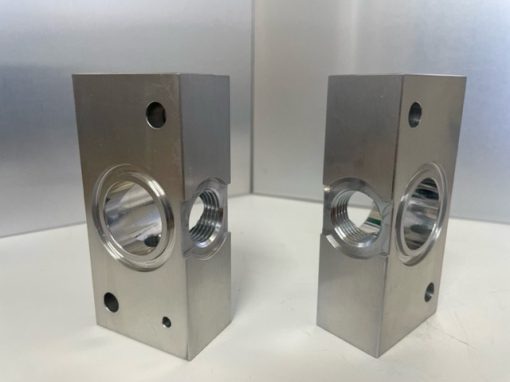

TWB Finishing offer both rack zinc plating and barrel zinc plating. Rack plating is used for larger more complex parts which are affixed to metal racks and placed inside the tank containing the plating bath. The parts remain stationary during plating It provides a uniform and aesthetically pleasing finish to your larger metal parts. Barrel plating is normally used for smaller parts and instead of a plating tank, the parts are placed inside a barrel and rotated providing a more uniform finish.

Zinc plating can be deposited in varying thicknesses depending upon the requirement. After plating parts are invariably passivated in a solution to enhance the corrosion resistance of the zinc deposit. Further treatments can be applied after passivation such as sealants to further improve corrosion resistance. TWB are also one of the few surface finishers able to offer zinc plating with an electropainted topcoat providing unrivalled corrosion resistance to the finished parts.

Work Envelope

240mm width

900 mm deep

1065mm long

Suitable Substrate

Mild Steel

Pre-treatment

It is essential to thoroughly clean the surface of the substrate prior to plating. Any debris or contaminants remaining on the surface will prevent proper adhesion of the zinc coating. An alkaline detergent solution is typically used for surface cleaning which can followed by the application of an acid treatment to remove surface rust. This latter procedure is referred to as pickling.

Post Treatments

Upon completion of the electroplating process the parts are ready for post-treatment. This normally involves rinsing the parts in water to remove any remaining contaminants and plating bath remnants The final step is to thoroughly dry the zinc-plated parts. In situations where additional corrosion protection is required, the application of passivates and sealers can be included in the post-treatment.

TWB can offer a range of passivates and sealants including;

- Clear / Blue passivate – Trivalent chromate ELV/RoHS compliant

- Yellow Passivate – Hexavalent chromate

- Black Passivate

- Rack Zinc Seal (An organic seal which offers up to + 120 hours to white rust and + 480 Hours to Red rust)

- Electro painted topcoat (Black)

Specifications

TWBFeZntxn

TWBFeZN’Yytxn

We can work to BS EN ISO2081 or OEM customer specifications as required

Benefits

- Provides an aesthetically attractive ‘bright’ finish to finished parts

- Improves corrosion resistance

- Seen as an environmentally friendly finish as zinc is recyclable

- Zinc plating offers a high temperature tolerance

- Works very well as an undercoat due to its excellent adhesion and ability to provide a strong base for a painted e-coat giving superior corrosion resistance (Link to E-paint)

- Large range of post treatments available to provide both increased corrosion resistance and different colour options.

Uses

Zinc plating is the most effective and cost-efficient way to treat steel parts in order to provide added corrosion resistance and protect parts from the effects of weather and temperature.

It is commonly used to plate small hardware items such as nails, screws, nuts, bolts, and fasteners. Zinc plating is also used extensively in the automotive industry on items such as brake pipes and callipers and steering components. Can be used on any steel part to provide both corrosion resistance and an attractive bright finish.

For more information about this service or any other please contact us