Overview

Iridite is a chemical process that produces a protective chrome conversion film on aluminium and its alloys. The coating offers corrosion protection and can be used as a final finish or the base paint or topcoats.

The process is environmentally friendly, a non–chrome passivate (NCP) to comply with the ELV, RoHS and WEE directives. Iridite does not contain lead, cadmium, chromium (hexavalent or trivalent) mercury or PBB / PBDE compounds.

But offers a corrosion resistance that is equal to hexavalent chromates on many aluminium alloys.

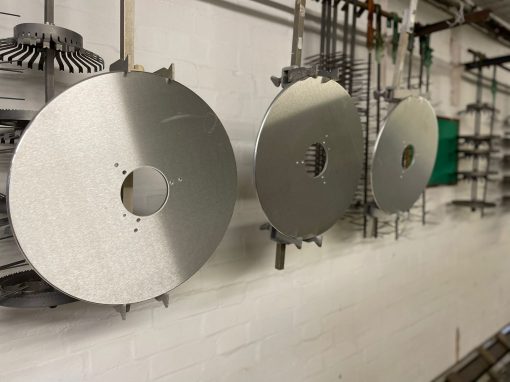

Work Envelope

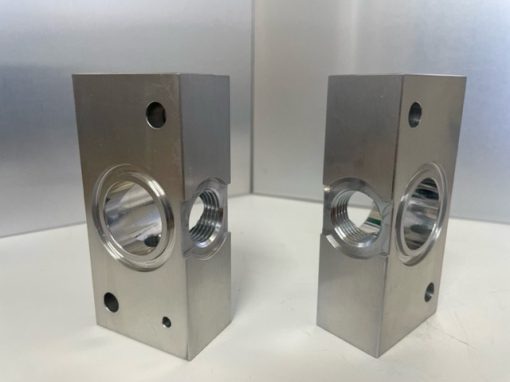

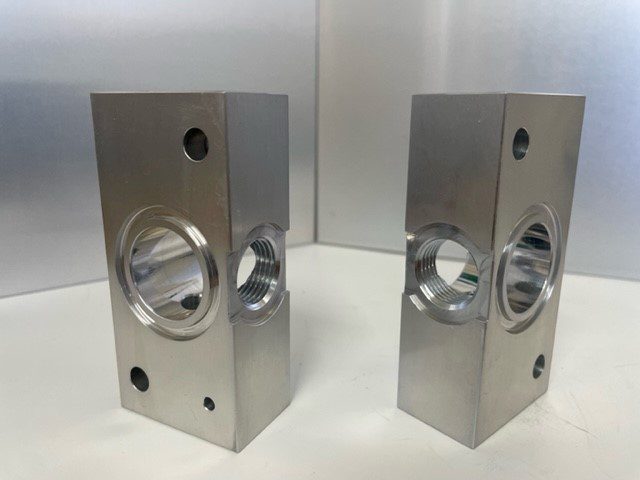

Suitable Substrate

Aluminium

Aluminium Alloys

Post Treatments

EP paint can be applied as a topcoat giving a far superior satl spray performance than with a standard paint finish.

Performance Specifications

Typical salt spray results range from a minimum of 96 hours to first white to 168 hours to first white corrosion.

Benefits

- Corrosion protection that can rival conventional chromate conversion coatings

- Electrical grounding ability and electrical resistance

- Eliminates the use of hexavalent and trivalent chromium.

- Provides excellent adhesion to paints, seals and adhesives

- No aging or curing is required before the application of topcoats

- Environmentally compliant meaning that it contains no hexavalent or trivalent chromium compounds

- It’s ability to withstand high temperatures makes it suitable for use on items with

- high operating temperatures such as automotive engine components

Uses

Iridite’s high resistance to bare corrosion means it is in demand for automotive, engineering, aerospace and military applications. Iridite processes are extensively used to clean, condition and protect all aluminum alloys and castings used in these industries. The Iridite coating also exhibits excellent adhesion characteristics making it an ideal base for further treatments. These properties are required for automotive industry and helps with the bonding of adhesives, seals and gaskets as well as multi component assembly. Iridite also provides functional electrical resistance as well as corrosion resistance making this treatment ideal for use on lightweight electric vehicles.

For more information about this service or any other please contact us