De-embrittlement (Hardening)

De-embrittlement is the process of hardening metal, specifically hydrogen-susceptible metals that have been exposed to hydrogen. Hydrogen exposure has the effect of making the metal more brittle and therefore susceptible to fracture. During metal finishing processes including cleaning, electroplating and heat treatments, hydrogen can be diffused into the metal parts. To rectify this a metal hardening process is administered after the metal has been subjected to an electroplating service. De-embrittlement is usually achieved between 220 and 240 degrees centigrade and can take 3-4 hours.

Shot-blasting

Shotblasting is a resurfacing process used to remove debris, contaminants and irregularities from metal parts. Shot blasting can also be used to strengthen (peen) metal parts via the process of ‘strain hardening’ allowing the metal to withstand greater stress.

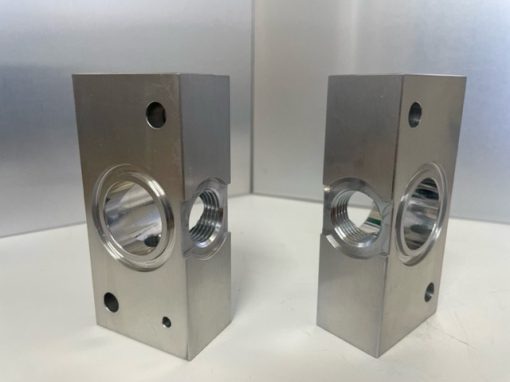

Masking

Some parts may require selective plating, for example in order to avoid excess build-up on fine machine threads. In such cases TWB are able to apply masking to these areas prior to processing in order to achieve the desired finish. TWB can also work with clients to advise on the best masking methods to use and work with our partners to create an effective masking solution.

Packaging

Our experienced packing team will ensure that your parts are packed ready for transit according to your requirements. TWB can advise on specific methods and materials to use to ensure that your parts can be transported onwards safely.